Ensuring precision and accuracy in using cutting linear guides machine involves several key practices and considerations:

-

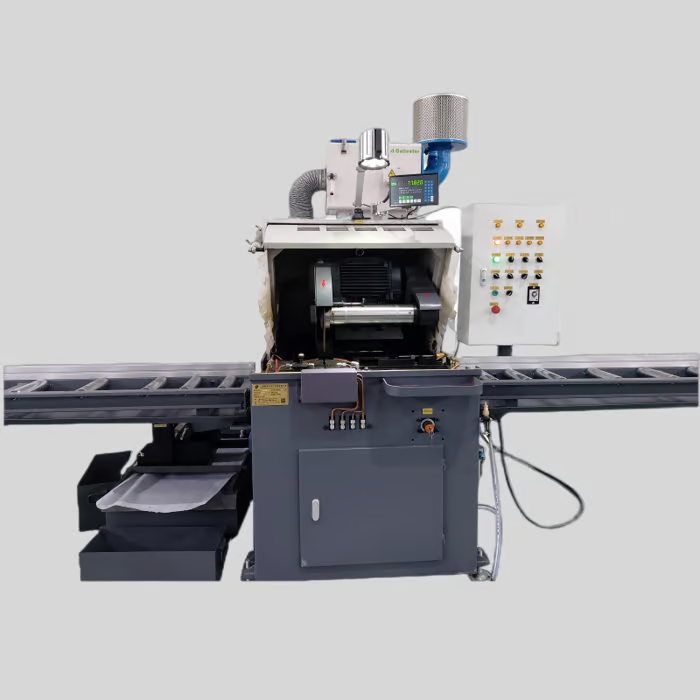

Use High-Quality Equipment:

- High-Quality Machines: Invest in reliable and well-maintained cutting machines that are known for their precision.

- Sharp and Proper Blades/Tools: Ensure the cutting blades or tools are sharp and appropriate for the material being cut.

-

Proper Machine Calibration and Setup:

- Calibration: Regularly calibrate the machine to ensure it is functioning correctly and cutting accurately.

- Alignment: Ensure the workpiece is properly aligned and secured before cutting. Misalignment can lead to inaccurate cuts.

-

Select the Right Cutting Parameters:

- Cutting Speed: Use the appropriate cutting speed for the material and thickness of the linear guide. Too fast or too slow can affect precision.

- Feed Rate: Adjust the feed rate to ensure smooth and consistent cutting without causing vibrations or deviations.

-

Maintain the Equipment:

- Regular Maintenance: Perform regular maintenance on the cutting machine, including lubrication, cleaning, and checking for wear and tear.

- Blade/Tool Replacement: Replace blades or cutting tools when they become dull or worn out.

-

Use CNC Machines for High Precision:

- CNC Programming: Utilize CNC (Computer Numerical Control) machines for tasks requiring high precision and repeatability. Proper programming and setup are crucial.

- Simulation and Testing: Run simulations and test cuts to ensure the program is correct and the machine is set up accurately.

-

Control Environmental Factors:

- Stable Work Environment: Ensure the cutting environment is stable and free from vibrations or movements that can affect precision.

- Temperature and Humidity: Maintain consistent temperature and humidity levels to prevent material expansion or contraction that could affect accuracy.

-

Measure and Inspect:

- Precision Measuring Tools: Use precision measuring tools such as calipers, micrometers, and laser measurement systems to check the dimensions of the cut linear guides.

- Quality Control: Implement a quality control process to inspect the cut pieces for accuracy and consistency.

-

Training and Skill:

- Operator Training: Ensure operators are well-trained and skilled in using the cutting machines and understanding the material properties.

- Continuous Improvement: Encourage a culture of continuous improvement where operators are always looking for ways to enhance precision and efficiency.

By combining high-quality equipment, proper setup and calibration, careful selection of cutting parameters, regular maintenance, and skilled operators, you can ensure precision and accuracy in cutting linear guides.